Differences Between 2 Wire and 3 Wire Well Pumps

What's the difference between 2-wire and 3-wire well pumps? We get that question often, and the answer can be difficult to find if you don't know the right questions to ask.

This article discusses the differences between 2-wire and 3-wire well pumps, how to tell which type you have, and how to make sure you're wiring your pump correctly when installing. Watch the video for our expert explanation.

The Difference Between 2-Wire and 3-Wire Well Pumps

For any type of electric deep well pump, the main differences in the wiring will depend on the horsepower of the motor running on the pump, and where the starting components on the pump are located (like the relay and start capacitor). Without getting into too much engineering and physics, just know that three-wire configurations are used in well pumps that demand more power to start and require motors larger than 1.5 HP (horsepower).

All well pumps will have a ground wire, but when distinguishing between the two types of well pumps, the ground wire is not counted.

Two-Wire Deep Well Pumps

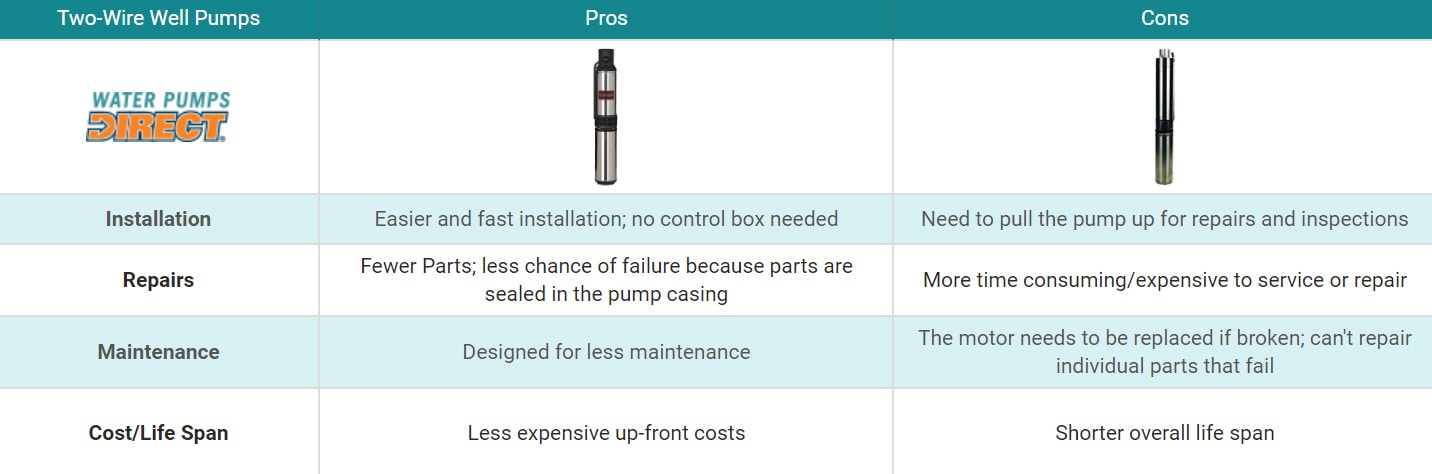

With the way 2-wire well pumps are configured, the motor will be connected by two black wires and a green ground wire. The starting components will be located inside the motor itself, making it much more difficult to access after installation should you ever need to inspect or repair the pump. In this case, you would have to pull the pump out of its installation location in order to inspect it.

With the way 2-wire well pumps are configured, the motor will be connected by two black wires and a green ground wire. The starting components will be located inside the motor itself, making it much more difficult to access after installation should you ever need to inspect or repair the pump. In this case, you would have to pull the pump out of its installation location in order to inspect it.

But, because everything is built inside the pump casing, installation is easier and faster as well. Two-wire pumps are also less likely to fail because of the way they are built and have fewer components overall. However, if a problem does occur, they are much more expensive to repair or replace.

Three-Wire Deep Well Pumps

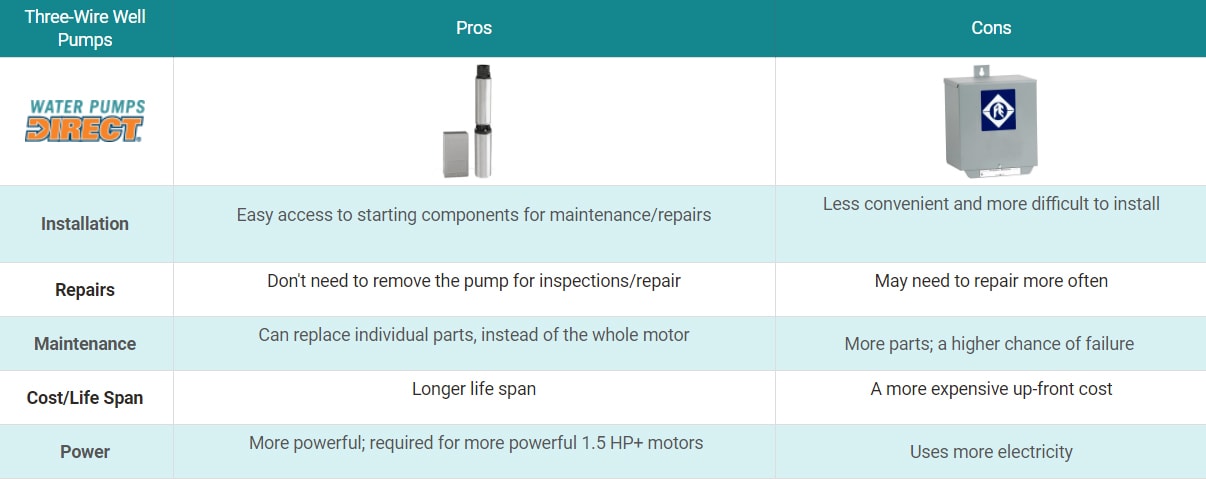

In a 3-wire well pump configuration, the motor is connected by a black, red, yellow, and green (ground) wire. Three-wire pumps utilize a separate control box outside the pump that houses the important starting components, which is usually mounted on a nearby wall above the ground. This makes installation more intensive, however, it makes it easier and cheaper to maintain and replace individual parts instead of the entire motor if something ever goes wrong.

In a 3-wire well pump configuration, the motor is connected by a black, red, yellow, and green (ground) wire. Three-wire pumps utilize a separate control box outside the pump that houses the important starting components, which is usually mounted on a nearby wall above the ground. This makes installation more intensive, however, it makes it easier and cheaper to maintain and replace individual parts instead of the entire motor if something ever goes wrong.

Though it is true that 3-wire pump configurations have more parts and thus a higher chance of needing repair and maintenance, the separate control box makes it simple to access the main components without having to remove the well pump from its installation location. Additionally, because there are more parts in a 3-wire system, it's possible that repairs would be cheaper and faster to fix since only one part of the system may need to work done, as opposed to the entire motor needing replacement in a 2-wire pump.

2-Wire vs 3-Wire Well Pumps: Which is Better?

Simply put, if the deep well pump you need has a motor larger than 1.5 HP, the safest bet is to go with a 3-wire well pump so it starts and runs properly. If your application doesn't require such a large well pump, then it comes down to a few purchase decisions.

Do you want to easily maintain the starting components of your pump and replace only the parts that break? Do you want to avoid having to pull the pump out of the basin in order to inspect it? If so, go with a 3-wire well pump. Three-wire pumps may have a higher starting price, but you're paying for the ability to replace individual parts of the pump, as well as a longer life span on the pump itself.

If you desire a cheaper starting price, quick and easy installation, and are fine with replacing the entire pump if something major goes wrong, then an all-in-one 2-wire well pump may be the right choice for you.

Replacing a Submersible Well Pump

It goes without saying, but before attempting to install or replace a well pump, make sure you know what you're doing, or call a professional instead—electricity is dangerous and incorrect wiring can ruin the pump. Whether you'll be performing the work or not, it's important to understand the type of well pump you currently have in order to choose a proper replacement. If it's a first-time installation, you'll need to know which is the right pump you need to make sure everything works correctly.

30-40 years ago, many installers installed 2-wire pumps without the ground wire. If you are replacing a current pump with only 2 wires, you WILL need to run that ground wire for the new pump.

Can I Replace a 3-Wire Pump With a 2-Wire Pump?

Technically, yes, but in order to do this, you would need to have a technician cap off the third wire that won't be used with the new pump. To go from a 2-wire pump to a 3-wire pump, however, a new third wire would need to be installed, and a control box would need to be installed in order to make the proper connections work.

Your owner's manual should have a well pump wiring diagram that describes the relationship between the wires and connections in your setup. This is called a wiring schedule, which you can also normally find inside the existing control panel, if applicable. From the manual/schedule, you'll be able to determine if the current well pump is a 2-wire or 3-wire pump. See your breaker panel in order to understand the voltage of your pump and determine if it is a 110v, 115v, 220v, or a 230-volt setup.

![]() NEXT: How to Choose the Right Well Pump

NEXT: How to Choose the Right Well Pump